FULL PRODUCTION SERVICE

50 years experience of fermentation and downstream processes

Full responsibility of the operation

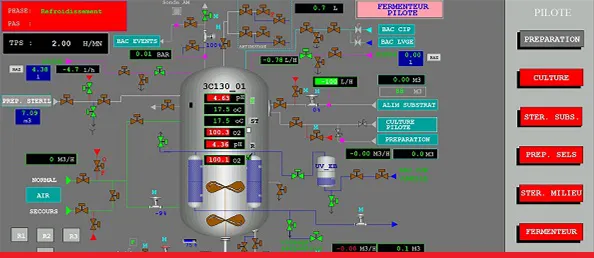

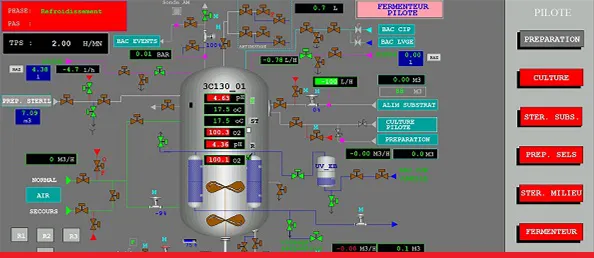

Extensive on-line monitoring

Waste management

Your process

Our asset

Your business

Our expertise

You have engineered a perfect microorganism and developed a breakthrough fermentation process that will serve a new business that will enhance the sustainability of the activities of your prospected partners. You have obtained the desirable results in your laboratory, and probably even made the demonstration that you can reproduce these results at pilot size. But are you willing to go to the industrial size on your own ?

Investing in industrial fermentation facility can request very high funds. Even if you succeed to raise such, building a team to operate a commercial stable manufacturing will prove to a much bigger challenge than you expected.

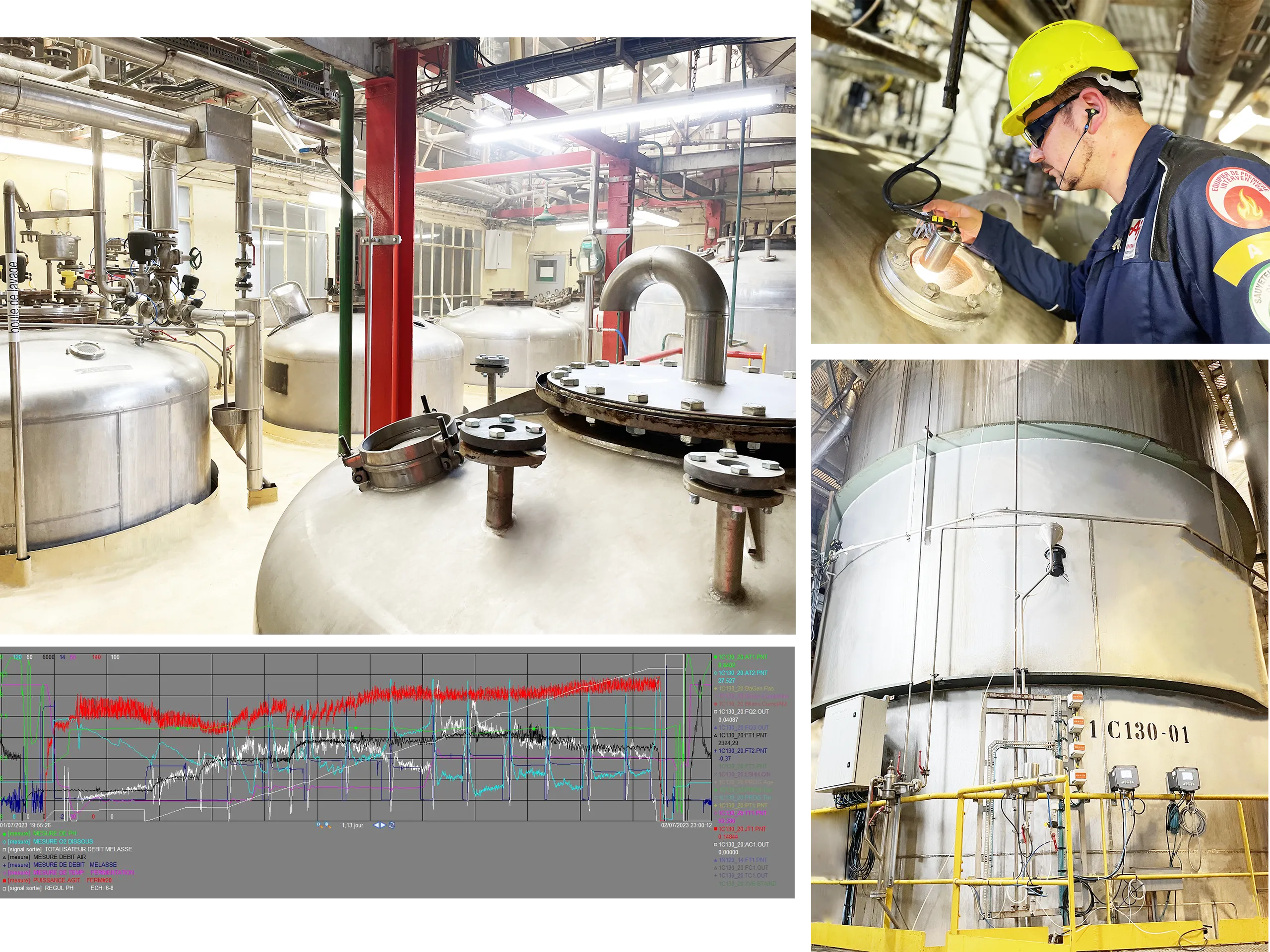

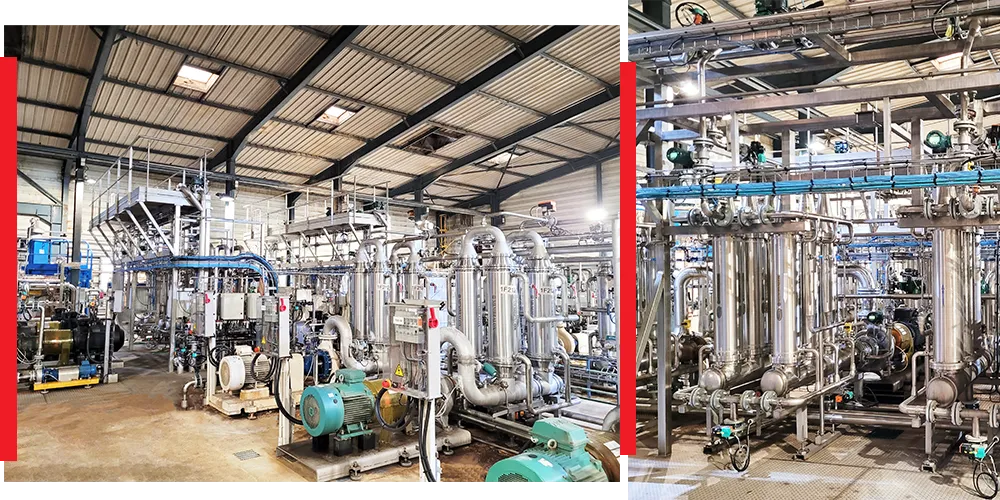

Ajinomoto Foods Europe Nesle plant has demonstrated over the past 20 years its expertise of fermentation scale-up, reliable manufacturing and process improvement. Our facility, located in north of France in an environment that ensures sustainable activity, includes cultures of more than 100 m³ and their associated equipment. We have served the food industry, but also some niche applications in cleaning agents, cosmetics or pharmaceutical. We have acquired the mastery of quality, safety, and environmental risks.

The good news is : we are proposing this asset and this experience as a service.

Possible adaptation to local substrates

Fine-tuning of the inoculation train

Vulnerability to parameters fluctuation

Smoother scale-up

Generation of large volume of samples

FULL PRODUCTION SERVICE

50 years experience of fermentation and downstream processes

Full responsibility of the operation

Extensive on-line monitoring

Waste management

SUPPLY CHAIN

Procurement scheduling

Storage of raw materials and final product

Shipment as you request

MANAGEMENT SYSTEM

Experienced system to manage control plans, release…

Benefit of our risks control and regulatory survey

Continuous improvement to optimize costs

Continuous sterilization systems

Intermediate cultures for biomass growth

Cell separation

Evaporation

Solid/Liquid separation

Crystallization

Drying

CUSTOMER COMMITMENT

We are committed to meet customer’s specific expectations in a collaborative approach.

We are committed to meet customer’s specific expectations in a collaborative approach.

SUSTAINABILITY

What we do and decide always integrates the intention to be able to do it perennially, drawing upon resources that can be renewed, and not harming any life or activity on Earth.

What we do and decide always integrates the intention to be able to do it perennially, drawing upon resources that can be renewed, and not harming any life or activity on Earth.

Constant innovation

We aim to be recognized for our ability to address the challenges our customers face, while striving to navigate unexplored areas of food science.

We aim to be recognized for our ability to address the challenges our customers face, while striving to navigate unexplored areas of food science.

VALUE PEOPLE

We consider each employee to be a unique individual, and we consider the development of skills, career growth and well-being at work to be key responsibilities of our management team.

We consider each employee to be a unique individual, and we consider the development of skills, career growth and well-being at work to be key responsibilities of our management team.

SOCIAL CONTRIBUTION

All our decisions and projects are designed to generate value that will be shared between our company and our stakeholders, e.i. our customers or other communities.

All our decisions and projects are designed to generate value that will be shared between our company and our stakeholders, e.i. our customers or other communities.

HIGH STANDARD

We always aim for the highest level of product reliability, the lowest possible risk to our employees and the environment, and maximum performance in every activity.

We always aim for the highest level of product reliability, the lowest possible risk to our employees and the environment, and maximum performance in every activity.

Our vision is deeply rooted in the fact that everything we do for any stakeholder has only value if it can be done in a perennial way. This means that we only use resources that we do not contribute to deplete, that we preserve the nature around us, that we maintain the skills of our employees and cultivate those of tomorrow, and that we strengthen our economic strength. To achieve all these ambitions, we use a comprehensive management system that ensures that we consider all the possible impacts of a project or change, that we analyze any deviations and eliminate their causes, and that we continuously measure and improve our performance.

Environment

Like any plant, our industrial activity has interactions with our environment : we use and reject water and air and generate some noise.

energy

As every fermentation site, our plant is using a lot of energy such as steam, electricity and cooling power.

Integration

We are proud to be completely integrated in the agricultural and industrial activity of our area. Our fermentation substrates come from local sugar or glucose factories, and our energy comes from sustainably managed forests of close regions.

Our company was founded 106 years ago with the discovery of “umami”. Our founder’s original aspiration, consisting of a “frontier spirit” and the “creation of new values”, is still at the core of Ajinomoto’s activities and preoccupations.

Ajinomoto® was exported to Taiwan in 1910, which is the next year of the company’s founding. The New York office was established in 1917. The number of countries and areas selling Ajinomoto Group products now exceeds 130.

Spread over 26 countries and areas around the world, the various employees of the Ajinomoto Group develop the business stemming from each local culture.

We are now developing plants in 21 countries and areas around the world, delivering safe and reliable products to customers throughout the world.

We offer seasonings, processed foods, beverages, pharmaceutical products, amino acids, specialty chemicals and other various products to the world.

The number of R&D workers of the Ajinomoto Group, which was approximately 100 in 1956, has highly increased with the growth of the business. This is why the Ajinomoto Group is said to be an unrivalled food company driven by technology